Traditionally potatoes are stored in bags on multiple floors, as high as 5 floors. Loading and unloading is done Manually. There are an estimated over 10,000 stores of varying capacities all over India.

However, in recent times, the industrial potato sector is gradually moving away from this bag storage system. Companies are recognizing the inefficiencies and quality deterioration associated with it and are shifting to modern storage systems that ensure better temperature control, longer shelf life, and reduced losses.

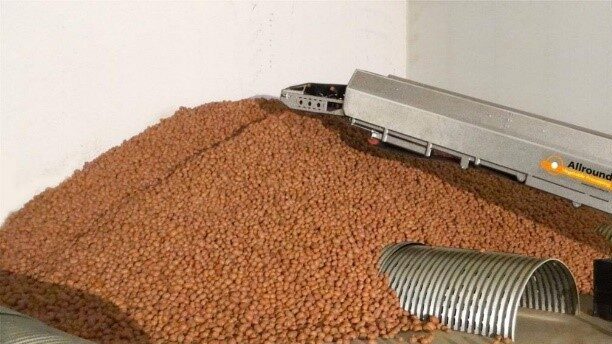

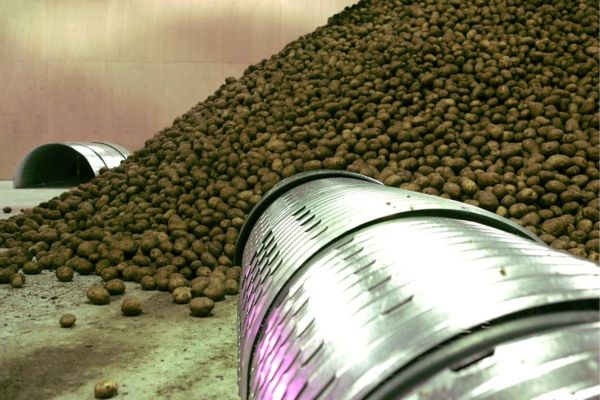

To address these challenges, modern cold storage solutions, such as bulk and box storages have been adopted. These advanced systems ensure uniform cooling critical for preserving the quality of potatoes.

While traditional potato storage methods remain prevalent in India, the shift towards modern, technologically advanced cold storage facilities offer a promising solution to the challenges faced by the industry. By adopting these advanced systems, India’s potato industry can significantly reduce post-harvest losses, improve supply chain efficiency, and ensure better quality produce for consumers. The transition to modern storage is not just a step forward in technology but also a leap towards sustainability and operational excellence.